Researchers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, have developed a groundbreaking solid-state thermoelectric refrigeration technology. Utilizing nano-engineered materials, this new approach is twice as efficient as devices made with conventional bulk thermoelectric materials. As global demand rises for energy-efficient, reliable, and compact cooling solutions, this innovation presents a scalable alternative to traditional compressor-based refrigeration.

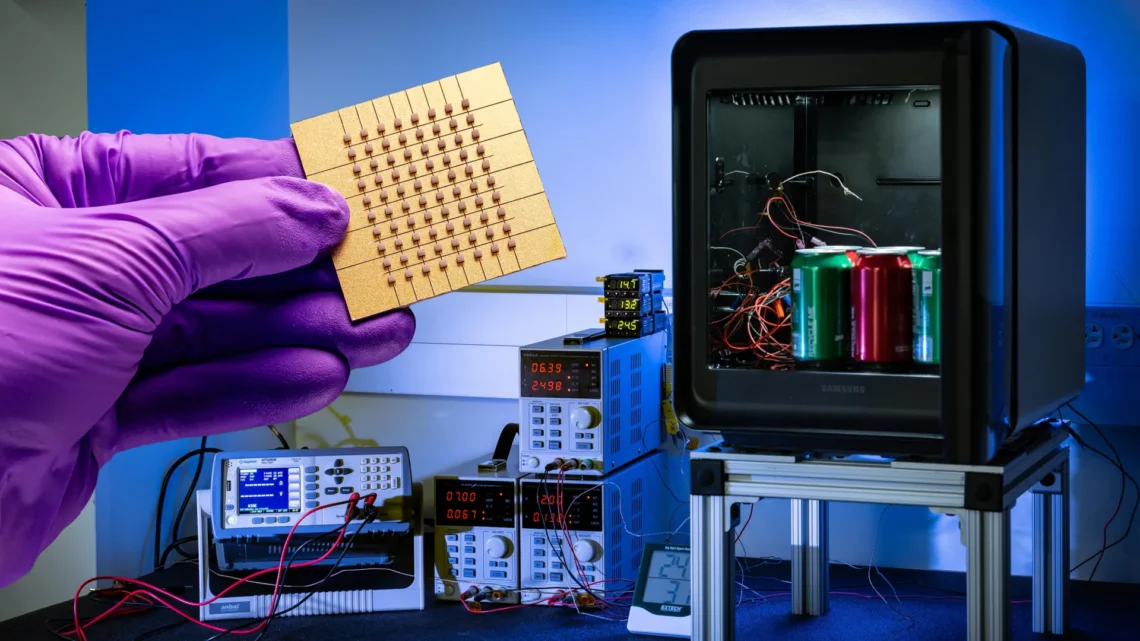

In a paper published in Nature Communications, a team from APL collaborated with refrigeration engineers from Samsung Research to showcase enhanced heat-pumping efficiency and capacity in refrigeration systems. This improvement stems from high-performance nano-engineered thermoelectric materials developed at APL, known as controlled hierarchically engineered superlattice structures (CHESS).

The CHESS technology reflects a decade of research at APL focused on advanced nano-engineered thermoelectric materials. Initially created for national security, these materials have also found applications in noninvasive cooling therapies for prosthetics and won an R&D 100 award in 2023.

“This real-world demonstration of refrigeration using new thermoelectric materials underscores the capabilities of nano-engineered CHESS thin films,” stated Rama Venkatasubramanian, the principal investigator of the project and APL’s chief technologist for thermoelectrics. “It represents a significant leap in cooling technology, paving the way for turning advances in thermoelectric materials into practical, large-scale, energy-efficient refrigeration applications.”

A New Benchmark for Solid-State Cooling

The drive for more efficient and compact cooling technologies is influenced by numerous factors including population growth, urbanization, and increasing reliance on advanced electronics and data infrastructure. While traditional cooling systems are effective, they tend to be bulky, energy-intensive, and rely on chemical refrigerants harmful to the environment.

Thermoelectric refrigeration is seen as a promising solution. This technology cools by using electrons to transfer heat through specialized semiconductor materials, doing away with moving parts and harmful chemicals. This makes these refrigerators quieter, smaller, more reliable, and sustainable. Although bulk thermoelectric materials are already used in small appliances like mini-fridges, their efficiency limitations and incompatibility with scalable semiconductor fabrication have hindered broader deployment in high-performance systems.

In their study, researchers compared refrigeration modules using conventional bulk thermoelectric materials to those using CHESS thin-film materials in standardized tests. They assessed the electrical power required to achieve various cooling levels in comparable commercial refrigerator systems. Samsung Research’s Life Solution Team, guided by executive vice president Joonhyun Lee, collaborated with APL to confirm the results through detailed thermal modeling, ensuring an accurate performance evaluation under real-world conditions.

The findings were compelling: employing CHESS materials, the APL team achieved nearly a 100% increase in efficiency over traditional thermoelectric materials at room temperature (around 80 degrees Fahrenheit, or 25 C). These material-level enhancements translated into a nearly 75% improvement in efficiency at the device level in thermoelectric modules built with CHESS materials, and a 70% increase in efficiency in fully integrated refrigeration systems—each demonstrating a significant edge over conventional bulk thermoelectric devices. These tests were conducted under conditions that simulated substantial heat pumping to mimic practical operation.

Built to Scale

Along with boosting efficiency, the CHESS thin-film technology uses remarkably less material—only about 0.003 cubic centimeters, roughly the size of a grain of sand, per refrigeration unit. This reduction means that APL’s thermoelectric materials can be mass-produced using standard semiconductor fabrication tools, promoting cost effectiveness and enabling widespread market adoption.

“This thin-film technology could evolve from powering small-scale refrigeration systems to supporting large building HVAC applications, in a manner similar to how lithium-ion batteries have been scaled from mobile phones to electric vehicles,” said Venkatasubramanian.

Moreover, the CHESS materials were created using a well-established process typically employed to manufacture high-efficiency solar cells that power satellites and commercial LED lights.

“We used metal-organic chemical vapor deposition (MOCVD) to produce the CHESS materials, a method known for its scalability, cost-effectiveness, and ability to support large-volume production,” said Jon Pierce, a senior research engineer leading the MOCVD growth capability at APL. “As MOCVD is already commercially prevalent, it’s ideal for scaling up production of CHESS thin-film thermoelectric materials.”

These materials and devices present significant potential for a wide range of energy harvesting and electronic applications beyond refrigeration. APL plans to further partner with organizations to refine the CHESS thermoelectric materials, aiming to boost efficiency to levels comparable to traditional mechanical systems. Future projects may include demonstrating larger refrigeration systems, including freezers, and incorporating artificial intelligence to enhance energy efficiency in divided or distributed cooling in refrigeration and HVAC systems.

“Aside from refrigeration, CHESS materials can also convert temperature differences, such as body heat, into usable power,” noted Jeff Maranchi, Exploration Program Area manager in APL’s Research and Exploratory Development Mission Area. “This advancement not only supports next-generation tactile systems, prosthetics, and human-machine interfaces but also opens avenues for scalable energy-harvesting technologies for applications ranging from computers to spacecraft—capabilities that older, bulkier thermoelectric devices could not offer.”

“The success of this collaborative effort illustrates that high-efficiency solid-state refrigeration is not just scientifically feasible but can also be produced at scale,” said Susan Ehrlich, APL technology commercialization manager. “We look forward to ongoing research and technology transfer opportunities with companies to bring these innovations into practical, real-world applications.”

Summary: Researchers from the Johns Hopkins Applied Physics Laboratory (APL) have unveiled a revolutionary solid-state thermoelectric refrigeration technology that is twice as efficient as conventional systems. Using nano-engineered materials, this new approach promises a more compact and environmentally friendly cooling solution. Collaborating with Samsung Research, APL demonstrated significant improvements in efficiency and performance. This breakthrough not only addresses the growing demand for energy-efficient refrigeration but also opens the door to broader applications in energy harvesting and electronics.